感覚を活用:ハイデフィニション・ハプティクス機能が運転の安全性を強化

2012年に、Tesla Model Sに大型スクリーンのセンター・コンソール・ディスプレイが導入されて以来、従来のような機械式の車両制御とスイッチは、統合型のタッチスクリーン・ユーザ・インターフェースに置き換えられることが多くなっています。このアプローチには、ソフトウェア・ベースのヒューマン・マシン・インターフェース (HMI) のすべての利点が備わっており、すっきりとしたインテリア・デザインを実現できますが、重要な車両制御の多くをセンタースタックのタッチコントロールに統合する傾向が高まるにつれ、使用中にユーザがディスプレイに目を向けなければならないという欠点があります。1

タッチスクリーン式のインフォテインメント・システムを使用する場合、ドライバの反応時間が50%以上長くなる可能性があることが研究で示されています。2将来的には、Euro NCAPなどの車両テスト機関が、ドライバの認知負荷を軽減し、道路から目を離さないようにするため、ハザードランプなどの重要な車両機能を制御する個々のボタンに対し、格付け評価プログラムにおいてポイントの割り当てを行うことを計画しています。3これは、すでに物理的な制御をタッチスクリーンHMIに置き換えた自動車メーカーにとって大きな課題となります。

-

ユーザはこのような「ソフトウェア定義」のアプローチに慣れています。ユーザが慣れ親しんでいるスマートフォンでのタッチスクリーン体験から彼らを引き離すには、同様に没入感のあるソリューションによってユーザの習慣を変える必要があります。

-

機械式ボタンに戻すことは、内装設計者の意向に反する可能性があります。例えば、スイッチを追加できるスペースがない場合や、洗練された「シャイ・テック」なインテリアの外観を「ボタンの島」で損ないたくないと考えている場合があります。

-

EVの普及が鈍化し、競争が激化する中で、業界の抱えるコスト圧力を考慮すると、個別の制御要素を追加するためのコスト上昇は、他の競合機能よりも正当性に欠けると思われるかもしれません。

このような逆境にもかかわらず、この課題を解決できるテクノロジーが存在します。

ソフトウェア定義の車両

一部の自動車メーカーはすでにタッチコントロールを導入していますが、機械制御から仮想ボタンへの移行は必ずしもスムーズではなく、当時の最高技術を用いたコスト最適化設計は市場であまり受け入れられませんでした。自動車の設計サイクルは最長で5年に及ぶため、新車のユーザ体験がコンシューマー・デバイスに遅れをとることがよくあります。これは、車両がショールームに並ぶ頃にはハードウェアがすでに古くなっており、ソフトウェアの更新と保守にコストがかかることが理由です。

自動車メーカーはこの分野に多額の投資を行っています。ソフトウェア定義の車両アーキテクチャーの登場により、自動車の生産開始とほぼ同時期まで、ユーザ向け機能の開発と完成を早めることができるようになりました。無線経由 (OTA) の機能更新は、車両が道路上で使用されるようになった後でも最適化が可能であり、新しい機能やパフォーマンスの微調整により、基盤のハードウェア設計を最大限に引き出すことができます。

自動車が購入する製品から、コネクテッド・モビリティ・エコシステムで使用するデバイスやサービスへと変化するにつれ、ユーザは、スマートフォンのユーザ体験に期待するのと同様に、使い慣れたアプリケーションを操作するためのデジタル・ネイティブな制御インターフェースを求めています。最近発売されたスマートフォンにカメラボタンが搭載されましたが、これは自動車業界で今後起こりうるトレンドを示唆しています。ユーザは、被写体をしっかりと見ながら撮影できるよう、スマートフォンでの撮影時に触覚的な操作を望んでいます。同じことが車にも当てはまります。ドライバは、道路から目を離さずにハンドルを持ち続けられるように、触覚制御を求めています。

ソフトウェア定義のコンセプトを車内制御に適用することで、まったく新しい可能性が生まれます。単純な機械式ボタンをシングル・クリックで機能するボタンに置き換えたとしても、システム全体に大きな価値をもたらすことはありません。一方で、プログラム可能な仮想サーフェスは、集中型HMI処理を活用して、さまざまな運転状況に応じて触覚フィードバックを即座に再構成することができます。これにより、各コントロールボタンの機能性が増し、ドライバの注意散漫を引き起こす可能性がある雑然とした状態が軽減されます。

この柔軟性により、自動車メーカーはNCAPが提案しているようなドライバ制御の安全性に関するガイドラインに適応しやすくなる可能性があります。ソフトウェア・ベースのアプローチを用いることで、多様な制御フィードバックに関する現地市場の好みや、安全性に関する規制やガイドラインを考慮して、地域ごとの調整を簡単に行うことができます。

クリックの生体構造

この記事のタイトルが示すように、最近の車両制御におけるハプティクス機能の導入による体験は、もっと向上させることが可能です。これは、必ずしも自動車用途に適した技術が不足しているためではありません。自動車用途の場合、物理的な堅牢性に関する要件とそれに関連するユースケースが大きく異なることが多く、コンシューマーレベルのハプティクス機能の導入が複雑であることに起因しています。

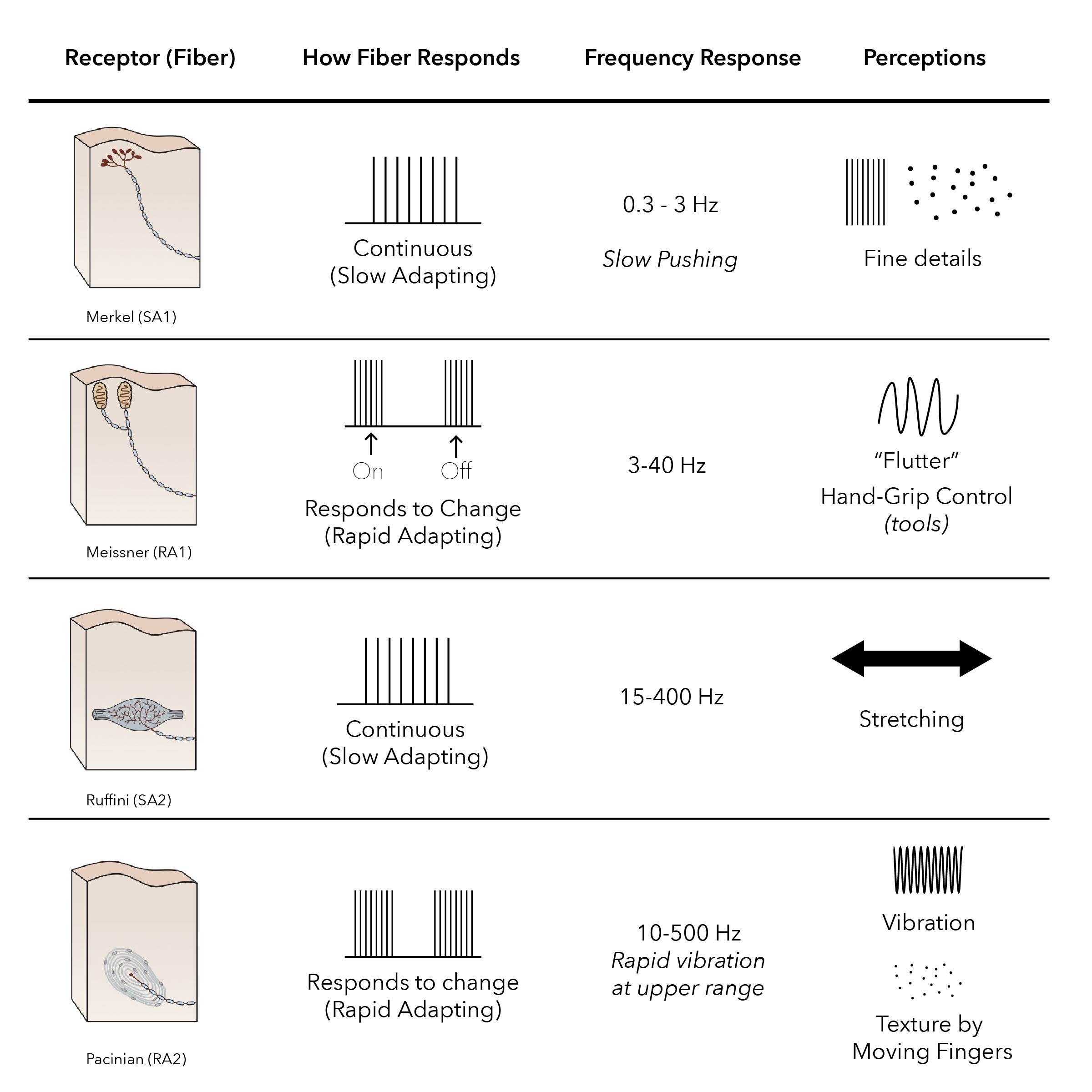

ハプティクス体験の安全性とリアルさを高める方法を理解するには、まず触覚フィードバックの構造を理解する必要があります。まず、生物学的な観点から見ると、人間の触覚システムには特定の機械受容体が備わっており、これにより、表面上で指を動かすときに最大500Hzの振動(RA2パチニア受容体)と質感を知覚できます(図1を参照)。これらの感覚で知覚できる強さと鋭さは、アクチュエータ(フィードバックを生成する機械的デバイス)がこれらの受容体を刺激する方法に直接関連しています。

クリックは主に2つの要素で構成されます。触覚の強さまたは力と、触覚の質です(図2を参照)。すべてのハプティクス・アクチュエータ技術が短くて強いクリック効果をネイティブに生み出せるわけではありません。

実際、現在道路上で使われている多くのシステムは、アクチュエータに一方向に「ブラインド」電圧パルスを送るオープンループのハプティクス回路を採用しています。設計において、ラボで触覚フィードバックの加速曲線を測定し、目的の効果が得られるまでパルス波形を修正することで、電圧パルスが最適化され、最大限のパフォーマンスが得られます。これはラボ環境では有効かもしれませんが、実際の環境では、製造時における部品間のばらつきや、その場の温度のばらつきにより、期待どおりのパフォーマンスが得られない可能性があります。その結果、機械受容体の能力を十分に活用できず、触覚フィードバック体験の質や安定性が低下する可能性があります。

ハイデフィニション・ハプティクス

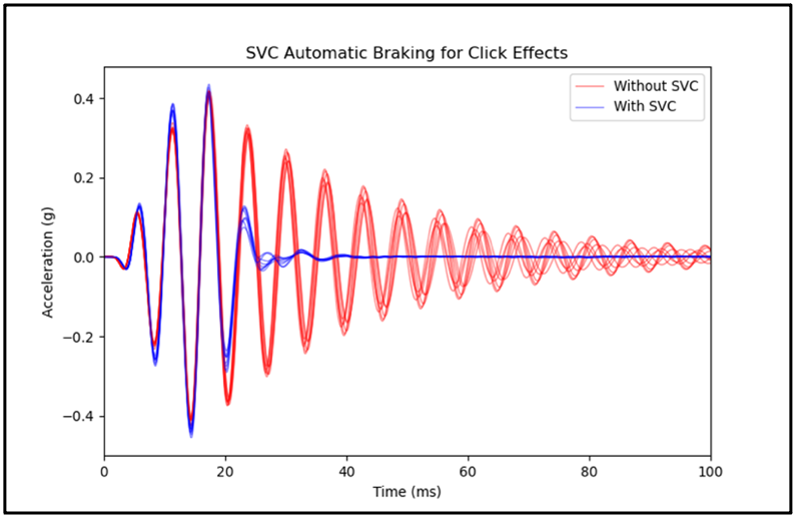

ノートパソコンのトラックパッドやスマートフォンで期待される体験と同等のより鮮明でより明確な触覚フィードバックを生成するには、Sensorless Velocity ControlTM (SVC) と呼ばれる方法を採用することで、より良い感覚が得られるHDハプティクス効果を生成できます。SVCは高度なアルゴリズムを使用しており、アクチュエータから戻ってくる信号を監視し、ドライブパルスとブレーキパルスの継続的な調整と補正を行って、可能な限り最高の「クリック」応答を実現します(図3を参照)。

SVCには多くのメリットがあります。例えば、クリック波形パルスにオーバードライブとブレーキを自動的に適用して顧客が望む加速仕様を実現できます。また、SVCの活用により、大量生産における製造公差や、実際の使用環境での温度変化にかかわらず、一貫したパフォーマンスを維持できます。これは、操作面に複数の異なるアクチュエータがある場合や、車室内に複数の操作面があり、同じ特徴的なクリックを示す必要がある場合に特に重要です。

クリックのパフォーマンスが車両の耐用年数にわたって維持されることも重要です。アクチュエータは時間の経過とともに老朽化するため、負荷インピーダンス、機械的剛性、共振周波数が変化することがあります。そうすると、オープンループ設計を採用したアクティブ・ハプティクス・システムのクリック応答が低下します。SVCを使用すると、アクチュエータの経時的な正常性を診断し、ドライバ出力波形にスマートなクローズドループ信号処理を適用することで経年劣化の影響を補正して、自動車のミッション・プロファイルのクリックを「鮮明」に保つことができます。

商業的な観点から見ると、SVCにより、パフォーマンスを犠牲にすることなく、アクチュエータの小型化やコスト削減が可能になります。しかし、最も重要なのは、タッチ入力フィードバックがより自然で認識しやすくなり、ドライバの認知負荷が軽減されることで、全体的なユーザ体験を向上させることができることです。

ハプティクスコントロールの簡素化

| 従来の分離型ソリューション | Cirrusの統合ソリューション |

|---|---|

|

|

| 低品質の「不鮮明」なハプティクス効果 | 鮮明で鋭敏な高精細の質感ハプティクス効果 |

| 複雑で時間のかかるソフトウェアとハードウェアの統合 | ハードウェアとソフトウェアの効率的な統合:ハプティクスの1チップ化 |

| シングル・アクチュエータ・サポート | 製造工程の最終段階での較正不要 |

| 製造工程の最終段階において工場でのコストのかかる較正が必要 | 製造工程の最終段階での較正不要 |

| ユニット間のパフォーマンスに一貫性がない | Sensorless Velocity Controlによる一貫したパフォーマンス |

クローズドループ制御を使用してハイデフィニション・クリックを実装することは難しく、フィードバックセンサー、高度なソフトウェアアルゴリズム、低遅延DSP処理を組み合わせた複雑なシステムが必要です。

図4は、そのような従来の「分離型」ハプティクスの実装をCirrusのアプローチと比較したものです。Cirrusのアプローチでは、さまざまな種類のアクチュエータを効果的に駆動するために必要なすべての回路をまとめた1チップ統合ドライバ・ソリューションを使用します。また、製造時における部品間のばらつきや環境の動作温度条件の変化にかかわらず、オンチップの電圧・電流モニタリングを使用してSVCを実装し、アクチュエータのパフォーマンスの積極的な検知と管理を行います。

CS40L5xシリーズでは、SVC機能に加えて、低遅延の波形生成と合成タスクをホスト・プロセッサからオフロードし、ハプティクス効果のみを生成します。数百もの異なるハプティクス波形をメモリに保存してストリーミングする必要はありません。ホスト・プロセッサは、より高レベルのスクリプトを使用して、さまざまなUIコンテキストに対するハプティクス効果のシーケンスを生成できます。これは、リソースに制約のあるデバイスにとって大きなメリットです。マイクロコントローラの使用コストを削減し、ソフトウェアの複雑さを軽減し、開発速度を上げることができます。

今後の展望

制御スイッチ用のアクティブ・ハプティクス・システムの従来の実装では、通常、ローカル・ソフトウェア・スタックを実行するマイクロコントローラと、トランスデューサを駆動する電圧パルスを生成するための個別の増幅器を組み合わせて使用します。ハプティクス効果は、通常、車両メーカーのガイドラインに基づいてスイッチ・モジュール・サプライヤによって開発され、車両の耐用年数にわたってスイッチ・ソフトウェアに「組み込まれて」います。OTAソフトウェアをアップデートすることでハプティクス効果を再構成できますが、そのためにはスイッチ・モジュール・サプライヤに変更を要請して必要なソフトウェアの変更を行う必要があります。

10Base-T1Sなどの最先端の車両通信ネットワークや、Open Alliance内で議論されているリモート制御のコンセプトを活用することで4、車両メーカーはスイッチ・ユニットのローカル・マイクロコントローラを中央の車両コンピュータで実行されるリモート制御ソフトウェア・ドライバに置き換えることが可能になります。スイッチ・ユニットのMCUは、I2CまたはSPIを介してハプティクス・ドライバに接続された統合I/O搭載のシンプルなネットワーク・トランシーバに置き換えられます(図5を参照)。

Cirrusハプティクス・ドライバは、ハプティクス・イベントの生成に必要なすべての信号処理機能と波形生成機能を備えているため、他のローカル・マイクロコントローラは不要です。

置き換えを実現する

Cirrusは、この記事で説明したSVCなどの機能のパフォーマンスをエンジニアが統合開発環境で測定・評価できるさまざまなハードウェアおよびソフトウェア・ツールを提供しています。Cirrus LogicのCS40L5xハプティクス・ドライバICファミリーと包括的なプロトタイピング・サポート・サービスの詳細については、automotivehaptics@cirrus.comまたは最寄りのCirrus Logic営業担当者にお問い合わせください。

執筆者

Peter Hall - 自動車事業開発マネージャー

Jorge Reynaga - ハプティクス製品マネージャー

Miguel Sanchez - ハプティクス・アプリケーション・エンジニア

i 「Properties of Four Types of Mechanoreceptors」 ダウンロード:https://mycourses.aalto.fi/pluginfile.php/910764/mod_resource/content/1/04%20-%20Activation%20Point.pdf 出典:Sensation and Perception, Seventh Edition Paperback – E. Bruce Goldstein(著者)

1 Matthew Avery氏(Euro NCAPの戦略開発ディレクター)はサンデー・タイムズ紙に次のように述べています。「タッチスクリーンの過剰使用は業界全体の問題です。ほぼすべての自動車メーカーが主要なコントロールを中央のタッチスクリーンに移行させています。その結果、ドライバが道路から目を離さざるを得なくなり、注意散漫による事故のリスクが高まっています。出典:https://etsc.eu/cars-will-need-buttons-not-just-touchscreens-to-get-a-5-star-euro-ncap-safety-rating/

2 運転中におけるAndroid AutoとApple CarPlayの操作:https://trl.co.uk/publications/interacting-with-android-auto-and-apple-carplay-when-driving

3 2026~2028年のNCAP評価計画8ページの「Driver Engagement」を参照。「運転操作は、重要性が極めて高い車両操作の使いやすさを評価する新しい評価要素である。」https://www.euroncap.com/media/79890/euro-ncap-rating-review-2023.pdf

4 TC18 – Remote Control Protocol(Open Allianceウェブサイト):https://opensig.org/tech-committee/tc18-remote-control-protocol/